In today’s fast-paced world, one such packaging solution that is crucial for businesses of all sizes is a shrink wrap packaging machine. This versatile piece of equipment offers numerous benefits, making it an indispensable tool in various industries. In this article, we will explore the key features, advantages, and applications of shrink wrap packaging machines.

What is a Shrink Wrap Packaging Machine?

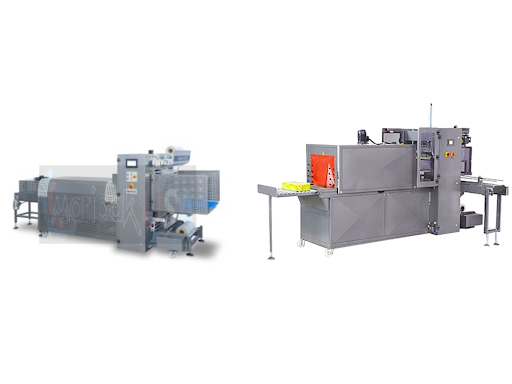

A shrink wrap packaging machine is a device that uses heat to shrink plastic film tightly around an item. The process involves placing the item inside the shrink film, sealing it, and then applying heat. The heat causes the film to contract, creating a secure, tight, and often tamper-evident package. These machines come in various sizes and configurations, from small manual units to fully automated systems, catering to different packaging needs.

Key Features of Shrink Wrap Packaging Machines

-

Versatility: Shrink wrap packaging machines can handle a wide range of products, regardless of shape or size. This makes them suitable for various industries, including food and beverage, pharmaceuticals, electronics, and consumer goods.

-

Efficiency: These machines offer high-speed packaging, significantly reducing the time required to package products. Automated systems can process hundreds or even thousands of items per hour, enhancing overall productivity.

-

Durability: The materials used in shrink wrapping provide a strong protective layer around the product. This protection helps to prevent damage during transportation and storage, ensuring that products reach consumers in perfect condition.

-

Clarity: Shrink wrap film is typically transparent, allowing consumers to see the product inside. This is beneficial for marketing purposes, as it enables potential buyers to inspect the product without opening the package.

Advantages of Using Shrink Wrap Packaging Machines

-

Cost-Effective: Shrink wrap packaging machines can reduce packaging costs significantly. The film is relatively inexpensive compared to other packaging materials, and the automation of the process reduces labor costs.

-

Space Saving: Shrink wrap reduces the volume of packaged products, allowing for more efficient use of storage and transportation space. This can lead to substantial savings in warehousing and shipping costs.

-

Environmental Benefits: Modern shrink wrap films are often made from recyclable materials, contributing to sustainability efforts. Additionally, the reduction in packaging material usage aligns with eco-friendly business practices.

-

Enhanced Product Presentation: The clear, tight-fitting film enhances the appearance of products, making them more attractive to consumers. It also allows for the addition of labels, barcodes, and other marketing materials directly onto the film.

-

Protection Against External Factors: Shrink wrap provides a barrier against moisture, dust, and other contaminants, preserving the quality and freshness of products, particularly in the food and beverage industry.

Applications of Shrink Wrap Packaging Machines

-

Food and Beverage Industry: Shrink wrap packaging is widely used for bundling multiple products together, such as packs of bottled water, canned goods, and snack foods. It ensures products are securely packaged and protected from contamination.

-

Pharmaceuticals: The tamper-evident nature of shrink wrap is crucial for packaging medicines and healthcare products. It helps maintain product integrity and safety, providing consumers with peace of mind.

-

Electronics: Shrink wrap packaging machines are used to package electronic devices and components, protecting them from dust, moisture, and static. This is essential for maintaining the functionality and longevity of these products.

-

Retail: Retailers use shrink wrap to package a variety of consumer goods, from cosmetics to household items. The transparency of the film allows consumers to see the product while keeping it secure and tamper-proof.

-

Logistics and Distribution: In the logistics industry, shrink wrap is used to stabilize pallet loads, ensuring products remain intact during transportation. This reduces the risk of damage and loss, improving overall supply chain efficiency.

Shrink film machines have become indispensable in the packaging industry with their versatile applications and numerous benefits. The heat shrink tunnel, a vital component of these machines, ensures uniform and efficient shrinking, resulting in professional and secure packaging.

Conclusion

Shrink wrap packaging machines have revolutionized the packaging industry by offering a versatile, efficient, and cost-effective solution for securing products. Their ability to provide tamper-evident, durable, and visually appealing packaging makes them an essential tool for businesses across various sectors.