Choosing the right butcher hooks is crucial for efficient meat processing. They are very much the unsung hero through the meat processing chain. Given the responsibility meat hooks carry (literally), they need to be made of sturdy stuff.

In the article, we are going to examine everything related to butcher hooks, from all the different kinds to their uses. Then, we’ll examine what they are used for at the top of the processing chain in abattoirs and slaughterhouses.

Then, to finish off, we’ll discuss the manufacturing process and what goes into making these workhorse items.

Here are some key considerations to help you make the best choice:

Types of Butcher Hooks Used in Meat Processing

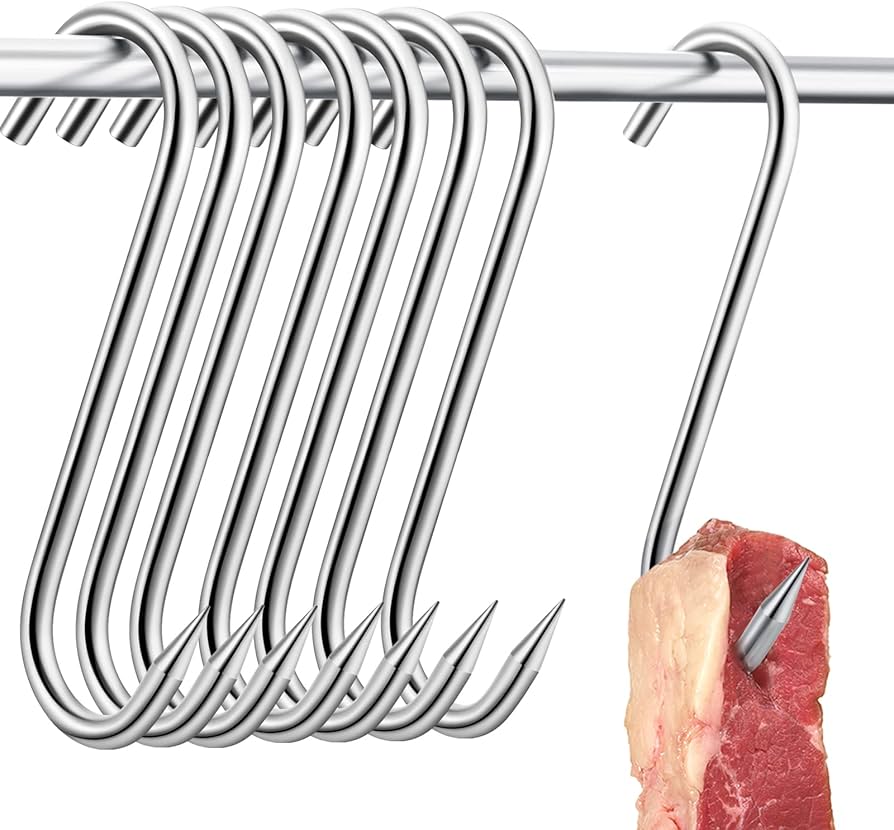

- S-Hooks: Ideal for hanging large cuts of meat.

- Gambrel Hooks: Perfect for smaller cuts like game birds.

- Curved Hooks: Suitable for smoked meats and bacon.

- V-shaped Hooks: Great for skewering oily fish.

Size and Shape

- Ensure the hooks are appropriately sized for the meat you are processing. The right size and shape will improve efficiency and safety.

Handle Design

- Choose hooks with ergonomic handles to minimise strain and maximise control. This is especially important for worker safety and productivity.

Sharpness and Maintenance

- Sharp hooks ensure clean punctures, reducing damage to the meat and preventing bacterial contamination. Regular maintenance is essential to keep the hooks in good condition.

Weight Capacity

- The hooks should be able to handle the weight of the meat without bending or breaking. Investing in high-quality hooks can save costs in the long run by reducing the need for frequent replacements.

The different Roles Butcher Hooks Play in Meat Processing

Butcher hooks play several critical roles in the processing stages within abattoirs and slaughterhouses. Here’s a detailed look at their functions:

Hanging and Transporting Carcasses

- Initial Hanging: After the animal is slaughtered, butcher hooks are used to hang the carcass. This allows for efficient bleeding and cooling.

- Transport: Hooks are essential for moving carcasses along rails or chains throughout the processing facility. This ensures a smooth workflow and minimises manual handling.

Skinning and Evisceration

- Skinning: Hooks help in suspending the carcass securely during the skinning process. This provides stability and ease of access for workers to remove the hide.

- Evisceration: During evisceration, hooks keep the carcass in place, allowing workers to remove internal organs without excessive movement.

Splitting and Cutting

- Splitting: Hooks are used to hold the carcass steady while it is split into halves or quarters. This is crucial for precision and safety.

- Cutting: Different types of hooks (e.g., S-hooks, gambrel hooks) are used to hang specific cuts of meat during further processing and cutting.

Inspection and Quality Control

- Inspection: Hooks facilitate the inspection process by allowing carcasses to be easily moved and rotated. This ensures a thorough examination of quality and safety standards.

- Quality Control: By maintaining the carcass in an optimal position, hooks help identify any defects or issues that need to be addressed.

Storage and Aging

- Cold Storage: Hooks are used to hang meat in cold storage rooms, allowing for proper air circulation and aging. This is essential for developing flavour and tenderness in the meat.

- Aging: During the aging process, hooks ensure that the meat is suspended in a way that prevents contamination and promotes even aging.

Packaging and Distribution

- Packaging: Hooks assist in holding the meat during the packaging process, ensuring that it is handled hygienically and efficiently.

- Distribution: For large-scale operations, hooks are used to hang and transport meat to different areas within the facility, streamlining the distribution process.

The Manufacturing Process of Boning Hooks

Material Selection

- Stainless Steel: The most common material for boning hooks due to its durability, corrosion resistance, and ease of cleaning.

- Carbon Steel: Sometimes used for its strength, though it requires a protective coating to prevent rust.

Cutting and Shaping

- Cutting: The stainless steel or carbon steel is cut into the desired length for the hooks.

- Shaping: The cut pieces are then shaped into hooks using specialised machinery. This involves bending the metal into the required hook shape.

Heat Treatment

- Hardening: The hooks undergo heat treatment to increase their strength and durability. This process involves heating the metal to a high temperature and then rapidly cooling it.

- Tempering: This step reduces brittleness by reheating the metal to a lower temperature and then allowing it to cool slowly.

Surface Finishing

- Polishing: The hooks are polished to remove any rough edges and to give them a smooth, shiny finish.

- Coating: If carbon steel is used, a protective coating (such as zinc plating) is applied to prevent rust and corrosionategroup.net.au/production-equipment/hooks-gambrels/.

Handle Attachment

- Ergonomic Handles: Handles made from materials like plastic or rubber are attached to the hooks. These handles are designed to provide a comfortable grip and reduce hand fatigue during use.

Quality Control

- Inspection: Each hook is inspected for defects and to ensure it meets quality standards. This includes checking the strength, sharpness, and overall finish of the hooks.

SUMMARY

By understanding these roles, you can appreciate how butcher hooks contribute to the efficiency, safety, and quality of the entire food processing chain all the way down to commercial kitchens, restaurants and your local butcher shop. Hanging meat has and always will be on of the fine arts in the industry to helping get that perfect cut.